Diagnose and measure changes in runway condition

Optimize your budget an value your pavement assets

- High performance of airfield runway condition surveying and rapidity of data acquisition

- Automated detection of damage and measurement of deformations

- Objective, reliable and comprehensive measures

- Accurate diagnostic analysis for scheduling preventive and remedial maintenance

- Flexible daytime and night-time servicing that does not interfere with operations

- Consulting, pavement engineering and decision-making support

Diagnostic and measure changes in runway conditions

Our teams deliver solutions tailored to your needs:

- Setting up a prevention data collection plan for the surveyed areas

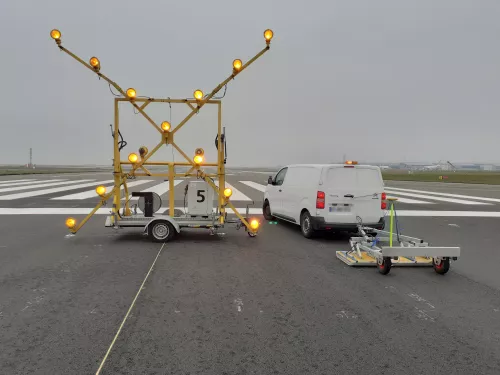

- Implementation of high-performance measurement systems: 7 types of measurements performed simultaneously

- Runway assessment using an automatic guiding

system in real time - Acquisition of 3D images of the runway to detect damage and measure deformations (acquisition process achieved in few hours)

- Recording the trajectory tracking, XYZ position and degradation position (Real Time Kinematic GPS system with and accuracy < 10 cm)

- Data post-processing, control and verification

- Calculation of the pavement condition indicators to determine the Pavement condition index

- Determination of longitudinal evenness according to waveband grade and IRI (International Roughness Index) indicators

- Provision of data that can be integrated into any Geographic Information System

Option to perform a supplementary structural diagnostic

Option to perform a supplementary structural diagnostic allowing to assess the bearing capacity of runways based on measures and studies such as :

• Deflexion with SHWD (Super Heavy Weight

Deflectometer)

• Pavement radar (continuously determining

homogenous areas and thicknesses of materials)

• Cores and surveys

• Laboratory tests (CBR Californian Bearing Ratio

and others)

• PCN calculations (Pavement Classification

Number)